Mechanical press machines are the backbone of the manufacturing industry, used to create parts and products that are essential to our daily lives. From car parts and appliances to toys and electronics, these machines are integral in producing the many objects we rely on.

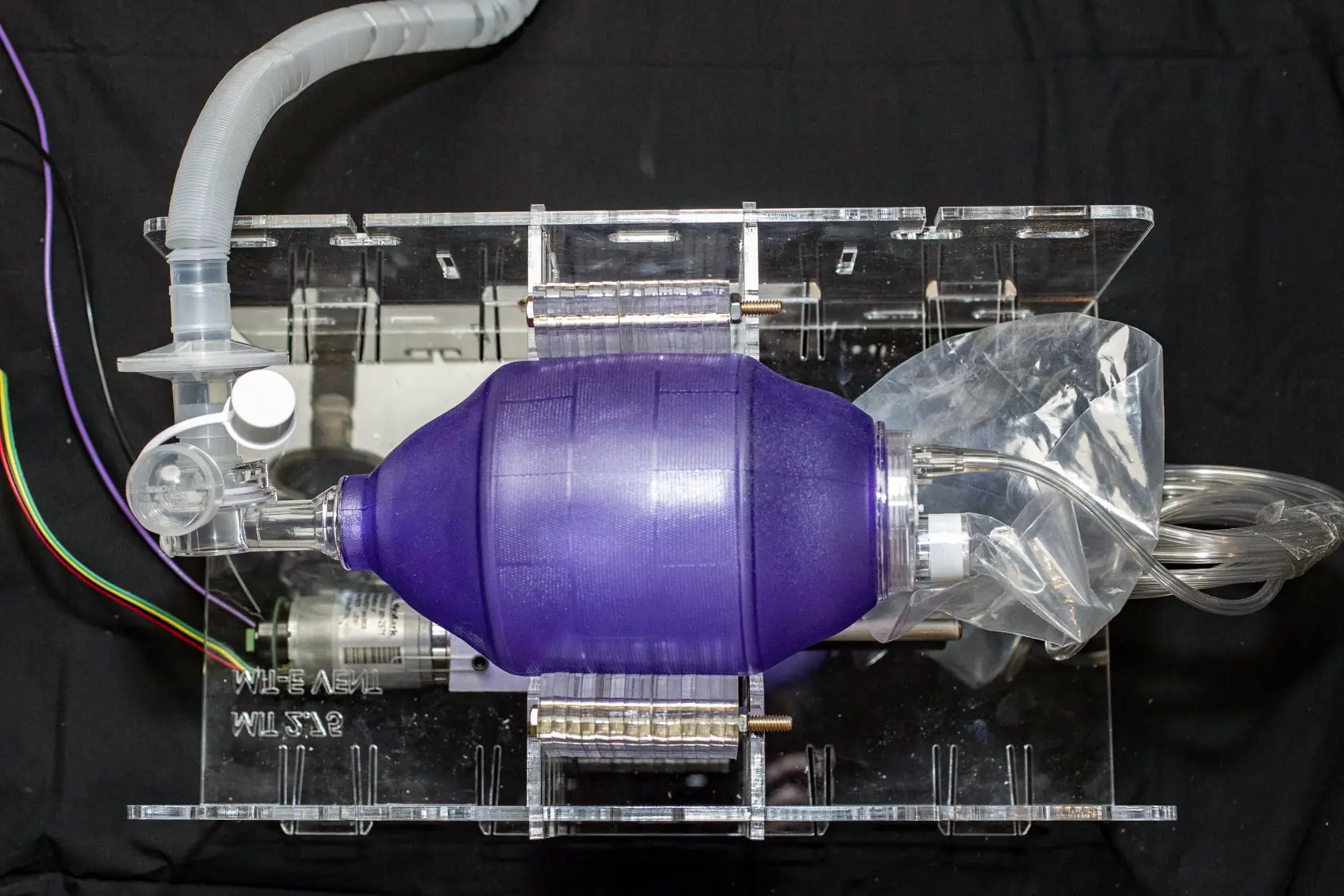

One application of mechanical press machines that has recently gained greater attention is their potential use in emergency ventilators, as seen with the MIT Emergency Ventilator. This has highlighted just how important these machines are to our healthcare system.

Mechanical press machines work by using mechanical energy to apply force and shape materials. They consist of a ram, which is the component that applies force to the material, and a bed or table, which provides a stable base for the material to be worked on.

There are three main types of mechanical press machines: flywheel, geared, and hydraulic. Flywheel press machines use a flywheel to store and release energy, while geared press machines utilize a gearbox to control the speed and force of the ram. Hydraulic press machines use hydraulic fluid to apply force to the material.

Each type of mechanical press machine has its own advantages and disadvantages. For example, hydraulic press machines are typically more accurate and can exert more force than flywheel or geared press machines. However, hydraulic machines also require more maintenance and have a higher initial cost.

Despite their differences, all mechanical press machines are vital to the manufacturing industry. They allow for the production of parts and products at a faster rate and with greater precision than manual methods, making them essential in keeping up with consumer demand.

In the case of emergency ventilators, mechanical press machines can be used to create components such as valves and regulators, which are crucial in ensuring the machine functions properly. This highlights the importance of having access to reliable and efficient mechanical press machines in times of crisis.

As technology continues to advance, mechanical press machines are also evolving to become more efficient and versatile. New features such as automation and digital controls are being added to make them easier to use and maintain.

In conclusion, mechanical press machines are integral to the manufacturing industry and play an important role in ensuring the production of essential parts and products. Their potential use in emergency ventilators has highlighted just how important they are to our healthcare system. As technology advances, we can expect to see continued innovation and improvement in these machines, making them even more vital to our daily lives.