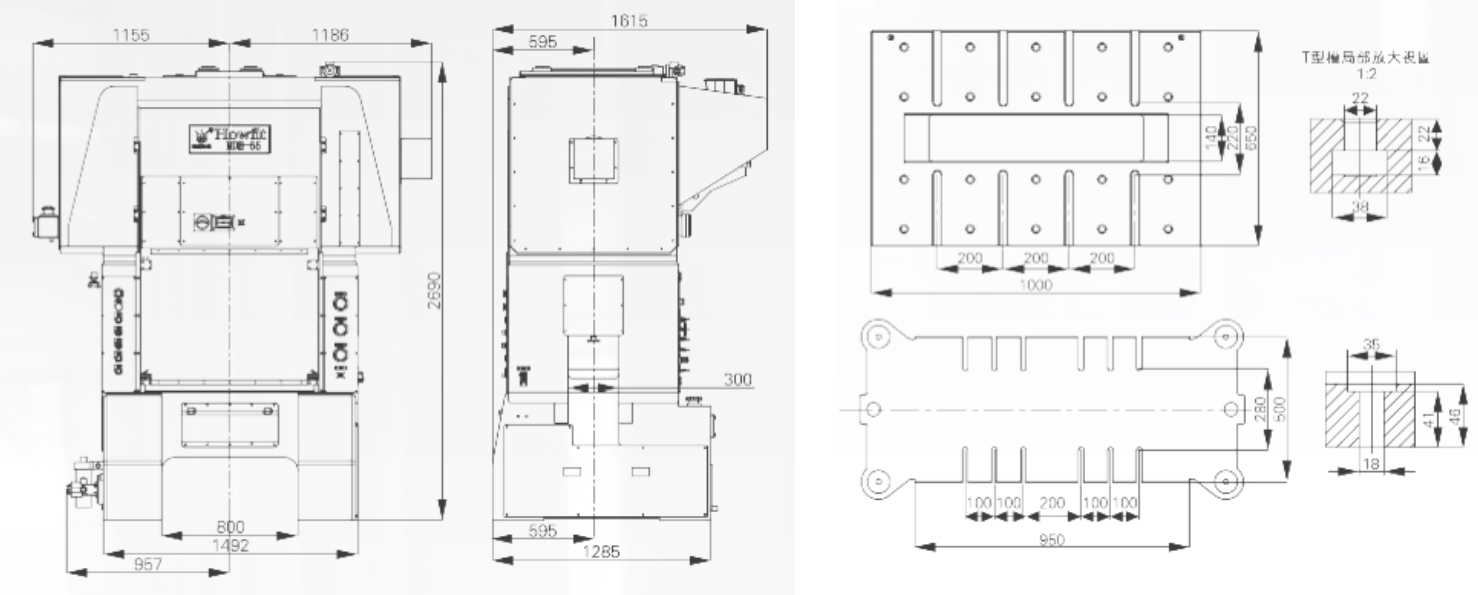

| Model | MDH-65T | |||

| Capacity | KN | 650 | ||

| Stroke length | MM | 20 | 30 40 | 50 |

| Maximum SPM | SPM | 700 | 600 500 | 400 |

| Minimum SPM | SPM | 200 | 200 200 | 200 |

| Die height | MM | 260 | 255 250 | 245 |

| Die height adjustment | MM | 50 | ||

| Slider area | MM | 950x500 | ||

| Bolster area | MM | 1000x650 | ||

| Bed opening | MM | 800x200 | ||

| Bolster opening | MM | 800(±)x650(T)x140 | ||

| Main motor | KW | 18.5x4P | ||

| Accuracy | JIS /JIS Special grade | |||

| Upper Die Weight | KG | MAX 300 | ||

| Total Weight | TON | 14 | ||

● The press frame adopts high-strength cast iron, and the internal stress of the workpiece is eliminated through natural long time after precise temperature control and tempering, so that the performance of the bed workpiece roachos the best state. ● The split gantry structure prevents the problem of opening of the machine body during loading and realizes the processing of high precision products. ● The crank shaft is forged and shaped by alloy steel and then machined by four-axis Japanese machine tool. The reasonable machining process and assembly process ensure that the machine tool has small deformation and stable structure during operation.

● The press frame adopts high-strength cast iron, and the internal stress of the workpiece is eliminated through natural long time after precise temperature control and tempering, so that the performance of the bed workpiece roachos the best state. ● The split gantry structure prevents the problem of opening of the machine body during loading and realizes the processing of high precision products. ● The crank shaft is forged and shaped by alloy steel and then machined by four-axis Japanese machine tool. The reasonable machining process and assembly process ensure that the machine tool has small deformation and stable structure during operation.

Question: Is Howfit A Press Machine Manufacturer Or A Machine Trader? Answer: Howfit Science and Technology CO., LTD. is a Press Machine manufacturer which specializes in High Speed Press production and sales with an occupation of 15,000 m² for 15 years. We also provides high speed press machine customization service to satisfy your specific requirements. Question: Is It Convenient To Visit Your Company? Answer: Yes, Howfit locates in Dongguan city, Guangdong Province, the South of China, where is nearby the main highroad, metro lines, transportation center, links to the downtown and suburbia, airport, railway station and convenient to visit. Question: How Many Countries Had You Been Successfully Made A Deal With? Answer: Howfit had been successfully made a deal with Russian Federation, Bangladesh, Republic of India, Socialist Republic of Vietnam, the United Mexican States, The Republic of Turkey, Islamic Republic of Iran, Islamic Republic of Pakistan and etc for so far.

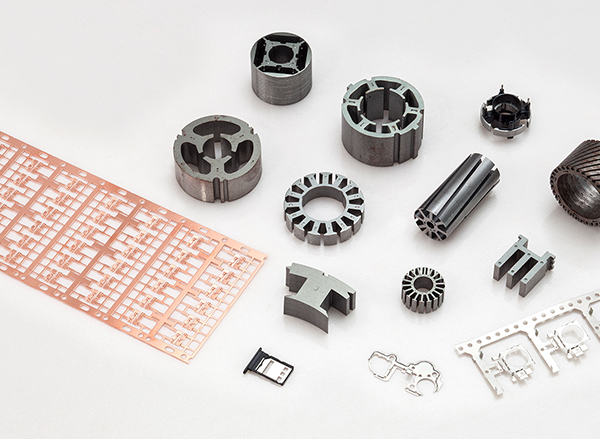

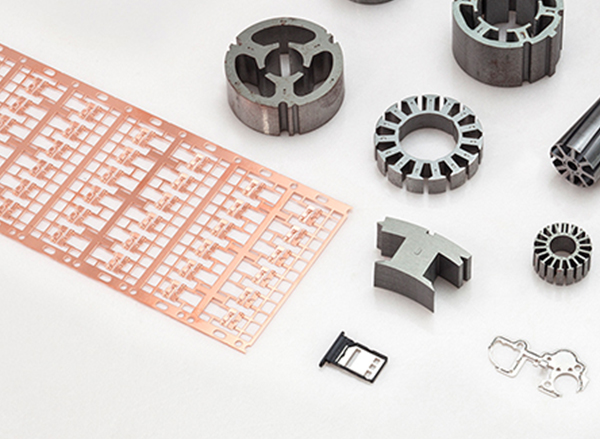

Question: Is Howfit A Press Machine Manufacturer Or A Machine Trader? Answer: Howfit Science and Technology CO., LTD. is a Press Machine manufacturer which specializes in High Speed Press production and sales with an occupation of 15,000 m² for 15 years. We also provides high speed press machine customization service to satisfy your specific requirements. Question: Is It Convenient To Visit Your Company? Answer: Yes, Howfit locates in Dongguan city, Guangdong Province, the South of China, where is nearby the main highroad, metro lines, transportation center, links to the downtown and suburbia, airport, railway station and convenient to visit. Question: How Many Countries Had You Been Successfully Made A Deal With? Answer: Howfit had been successfully made a deal with Russian Federation, Bangladesh, Republic of India, Socialist Republic of Vietnam, the United Mexican States, The Republic of Turkey, Islamic Republic of Iran, Islamic Republic of Pakistan and etc for so far. ● The press adopts 4 post guide and 2 plunger guide guiding structure, which can reasonably control ths displacement deformation between workpi&ces. Together with the forced oil supply lubrication system, the machine tool can minimize the slight thermal deformation under long time operation and partial load condition,which can guarantee ths long time high precision product processing. ● Human-machine interface microcomputer control, to achieve the visual management of the operation, th© number of products, machine status at a glance (the subsequent adoption of a central data processing system, a screen to know all machine work status, quality, quantity and other data).4 Post Guide and 2 Plunger Guide Gantry Type Precision series (press machine, punching press, punching machine,mechanical power press, stamping press), capacity from 60ton to 450ton, PLC control, wet clutch, hydraulic overload protected, High steel alloy casting frame structure (with the most suitable for the frame designed by computer analysis), processed by the internal stress elimination process, further improving the high rigidity frame which is indispensable for precision, achieving low noise and low vibration, and improving service life of the die. In addition to the following advantages: 1). Punch with waste blowing assembly. And in the middle of the working table is a waste tank. 2). Punch cutting dead center position is generally controlled by pressure switch, position sensor. 3). Such as customer needs can also design a fast and slow speed (generally fast close to the product when deceleration and pressure. 4). With automatic counting function, break up and semi-automatic two control modes, manual can be pressed on the mold stop in any range of travel, equipped with emergency pick up button, can also be equipped with infrared guard device. At present, China's die technology is relatively mature, but there is still a long way to go to perfect. The development direction of die Motor Core High Speed Punch Press tool technology is analyzed. Under the traction of the product market towards more varieties, fewer batches, and the fast changing speed of renewal, driven by new manufacturing technologies such as computer technology, the manufacturing technology of die design is being set up by computer aided design, relying on manual experience and conventional machinery plus technology. Computer Aided Design (CAD) with design, NC cutting and NC electrical machining as its core has changed its manufacturing direction.

● The press adopts 4 post guide and 2 plunger guide guiding structure, which can reasonably control ths displacement deformation between workpi&ces. Together with the forced oil supply lubrication system, the machine tool can minimize the slight thermal deformation under long time operation and partial load condition,which can guarantee ths long time high precision product processing. ● Human-machine interface microcomputer control, to achieve the visual management of the operation, th© number of products, machine status at a glance (the subsequent adoption of a central data processing system, a screen to know all machine work status, quality, quantity and other data).4 Post Guide and 2 Plunger Guide Gantry Type Precision series (press machine, punching press, punching machine,mechanical power press, stamping press), capacity from 60ton to 450ton, PLC control, wet clutch, hydraulic overload protected, High steel alloy casting frame structure (with the most suitable for the frame designed by computer analysis), processed by the internal stress elimination process, further improving the high rigidity frame which is indispensable for precision, achieving low noise and low vibration, and improving service life of the die. In addition to the following advantages: 1). Punch with waste blowing assembly. And in the middle of the working table is a waste tank. 2). Punch cutting dead center position is generally controlled by pressure switch, position sensor. 3). Such as customer needs can also design a fast and slow speed (generally fast close to the product when deceleration and pressure. 4). With automatic counting function, break up and semi-automatic two control modes, manual can be pressed on the mold stop in any range of travel, equipped with emergency pick up button, can also be equipped with infrared guard device. At present, China's die technology is relatively mature, but there is still a long way to go to perfect. The development direction of die Motor Core High Speed Punch Press tool technology is analyzed. Under the traction of the product market towards more varieties, fewer batches, and the fast changing speed of renewal, driven by new manufacturing technologies such as computer technology, the manufacturing technology of die design is being set up by computer aided design, relying on manual experience and conventional machinery plus technology. Computer Aided Design (CAD) with design, NC cutting and NC electrical machining as its core has changed its manufacturing direction.